Automatic heating filling fitting BA 6628 Plus DN20 for heating systems

Automatic heating filling fitting BA 6628 Plus DN20 for heating systems is in stock and will be shipped as soon as it is available again

Delivery and shipping

Delivery and shipping

Processing time is typically 1 business day. Delivery for parcels is 1-3 business days. For freight forwarding, delivery time is 3-5 business days. Delivery times outside Germany vary.

Description

Description

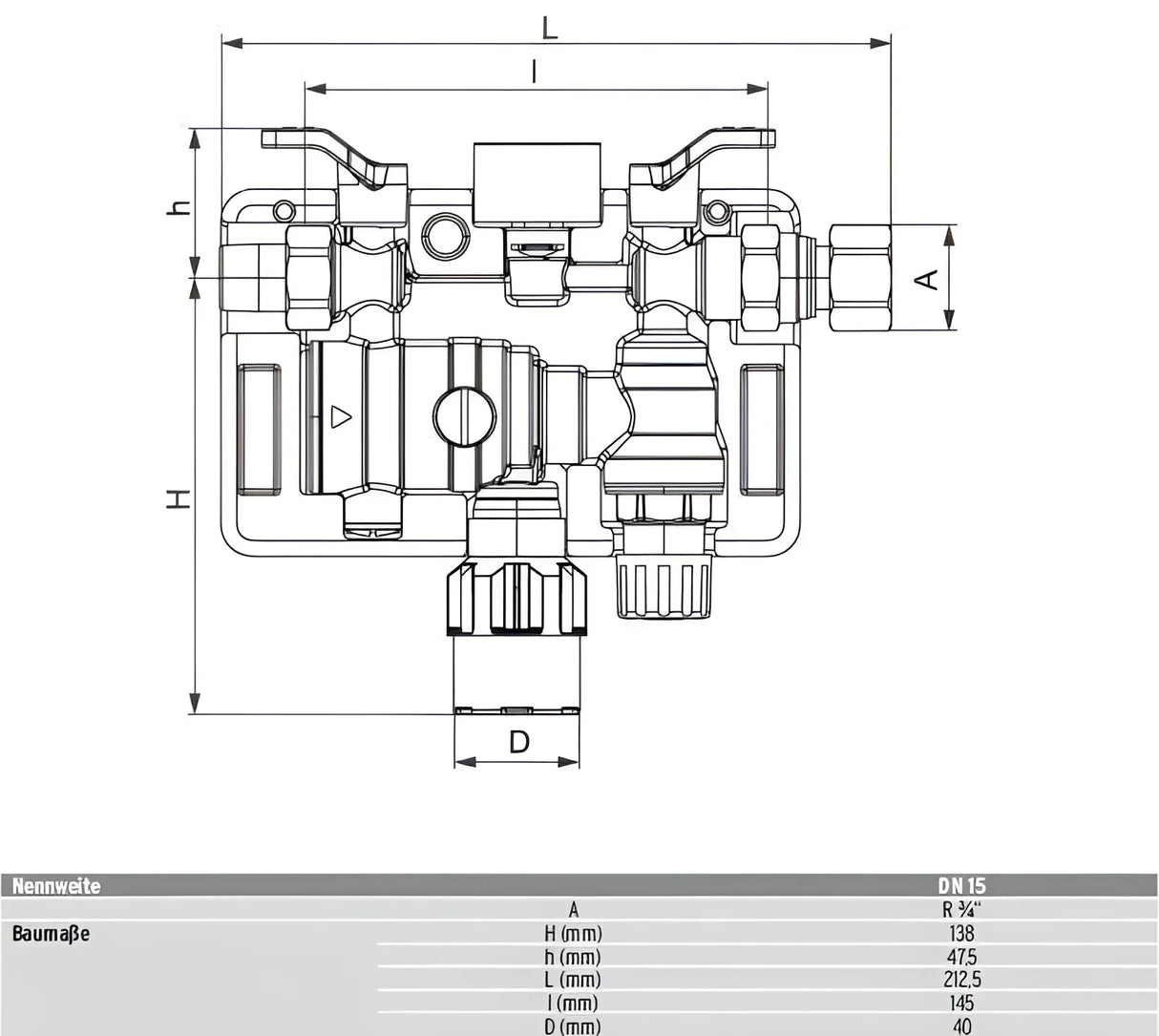

The automatic heating filling valve DN20 ¾" BA 6628 plus ensures the reliable and safe filling of closed hot water central heating systems in accordance with DIN EN 12828. Equipped with an integrated pressure reducer, pressure gauge, and BA system separator, this filling valve offers optimal protection against the backflow of heating water into the drinking water line, even in systems containing inhibitors such as corrosion or antifreeze agents. The fixed connection according to DIN EN 1717 and the automatic refill function make the automatic heating filling valve the ideal choice for modern heating systems.

payment & Security

Payment options

Your payment information is processed securely. We do not store or access your credit card information.